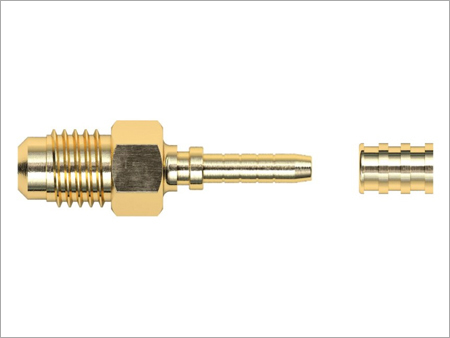

Straight Male Fitting

Price 1000 - 4000 INR/ Number

Straight Male Fitting Specification

- Medium

- Air, Water, Inert Gas

- Hardness

- Shore D 63-65

- Shape

- Straight

- Connection Type

- Male Threaded

- Cover

- Nickel Plated

- Material

- Brass

- Temperature

- -20C to 100C

- Pressure

- 0-16 Bar

- Inside Diameter

- 4 mm

- Outside Diameter

- 6 mm

- Leakage Proof

- Yes

- Installation

- Push-To-Connect

- Finish

- Nickel Coated

- Thread Type

- BSPT (British Standard Pipe Tapered)

- Working Life

- 50000 cycles

- Usage

- Pneumatic Tubing Connections

- Color

- Silver/Blue

- Thread Size

- 1/4 inch

- Corrosion Resistance

- Yes

Straight Male Fitting Trade Information

- Minimum Order Quantity

- 25 Number

- Supply Ability

- 25 Per Day

- Delivery Time

- 24 Hours

About Straight Male Fitting

Features:

- Accurate dimension

- Best in quality

- Longer operational life

- Durable construction

Robust Nickel Coating for Enhanced Durability

Featuring a nickel-plated finish, this male pneumatic fitting offers superior resistance to corrosion in demanding environments. The coating not only extends the product lifespan but also maintains its appearance and functionality even after extensive use.

Effortless Installation with Push-To-Connect Design

The push-to-connect system eliminates the need for specialized tools, making installation straightforward and hassle-free. This feature significantly reduces downtime and enhances efficiency, particularly in high-volume industrial or commercial settings.

Reliable Performance across Varied Applications

With compatibility for air, water, and inert gas mediums, this fitting delivers consistent, leak-proof performance. Its sturdy brass material and Shore D 63-65 hardness withstand intensive use, suited for automation systems, workshops, and manufacturing plants.

FAQs of Straight Male Fitting:

Q: How is the straight male BSPT fitting installed for pneumatic tubing connections?

A: Installation is simplified thanks to the push-to-connect mechanism. Simply insert the tubing into the fitting until it clicks into place. No additional tools are required, ensuring a quick and secure assembly.Q: What are the main benefits of the nickel-coated brass construction?

A: Nickel-coated brass offers exceptional resistance to corrosion, enhancing the fittings durability in harsh or moist environments. This ensures longer service life and maintains a reliable seal throughout its working life of up to 50,000 cycles.Q: When should I use this fitting with pneumatic tubing systems?

A: This fitting is ideal when you require a secure, leak-proof connection in pneumatic systems transporting air, water, or inert gases, especially where pressure ranges from 016 bar and temperatures between -20C to 100C are encountered.Q: Where can this straight male BSPT fitting be applied?

A: It is suitable for use in a wide range of industries, including manufacturing plants, workshops, automation lines, and laboratories. Its robust construction and easy installation make it especially attractive for distributors, suppliers, and traders in India.Q: What makes this fitting leakage-proof in demanding applications?

A: Its tapered BSPT thread ensures tight, secure connections, complemented by a precise push-to-connect mechanism. This design prevents leaks, offering dependable sealing even under fluctuating pressures and temperatures.Q: Is this fitting suitable for both high and low temperature applications?

A: Yes, the fitting is engineered to perform dependably across a broad temperature range from -20C to 100C, making it suitable for most pneumatic and fluid conveyance scenarios involving air, water, or inert gases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refrigeration Hose Fittings Category

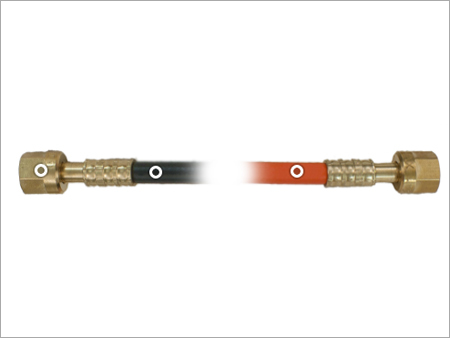

Dn2 Microbore Hoses

Price 1000 - 4000 INR / Number

Minimum Order Quantity : 50

Material : Other, Thermoplastic with synthetic fiber reinforcement

Inside Diameter : 2 mm

Cover : Polyamide (PA) or Polyurethane (PU)

Medium : Other, Hydraulic Oil, Air, Water etc.

SAE Elbow Female 90

Price 1000 - 4000 INR / Number

Minimum Order Quantity : 50

Material : Other, Carbon Steel / Stainless Steel

Inside Diameter : 1/4 inch to 2 inch

Cover : Oil and Weather Resistant Synthetic Rubber

Medium : Other, Hydraulic Fluids, Oil, Water

Microbore Hose Fittings

Price 1000 - 4000 INR / Number

Minimum Order Quantity : 50

Material : Other, Carbon Steel, Stainless Steel

Inside Diameter : 2 mm to 6 mm

Cover : Polyurethane or PVC

Medium : Other, Hydraulic Oil, Air, Water

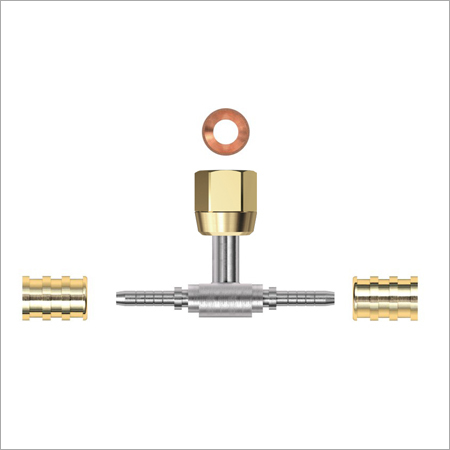

T Fitting With Female

Price 1000 - 4000 INR / Number

Minimum Order Quantity : 50

Material : Other, Brass

Inside Diameter : 1/2 inch to 2 inch

Cover : Nickel Plated

Medium : Other, Water, Gas, Oil

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese