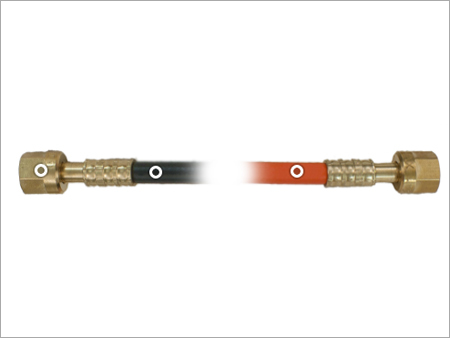

Dn2 Microbore Hoses

Price 1000 - 4000 INR/ Number

Dn2 Microbore Hoses Specification

- Cover

- Polyamide (PA) or Polyurethane (PU)

- Connection Type

- Crimped Male/Female or Quick Connect

- Hardness

- High

- Reinforcement

- Steel Wire Braided

- Medium

- Hydraulic Oil, Air, Water etc.

- Shape

- Round

- Material

- Thermoplastic with synthetic fiber reinforcement

- Temperature

- -40C to +100C

- Pressure

- Up to 630 bar

- Inside Diameter

- 2 mm

- Outside Diameter

- 5 mm

- Application

- High pressure testing, Pressure gauge lines, Fluid monitoring, Hydraulic systems

- Weight

- Approx. 0.04 kg/m

- Color

- Black/Blue/Yellow

- Minimum Bending Radius

- 15 mm

- Length Available

- Up to 100 meters (custom lengths available)

- Burst Pressure

- Up to 2500 bar

- End Fittings

- Stainless Steel/Brass fittings, M16x2, G1/4 etc.

Dn2 Microbore Hoses Trade Information

- Minimum Order Quantity

- 50 Number

- Supply Ability

- 50 Per Day

- Delivery Time

- 24 Hours

About Dn2 Microbore Hoses

Features:

- Heat resistance

- Easy fitting

- Rust resistance

- High endurance

Precision Engineering for Demanding Applications

Dn2 Microbore Hoses are crafted to meet the stringent requirements of high-pressure hydraulics, testing, and fluid transfer, excelling even under the toughest conditions. The steel wire-braided reinforcement grants durability and a high burst pressure, ensuring resilience during use. Their high hardness and polyamide or polyurethane cover further protect against abrasion and harsh external factors.

Flexible Lengths and Versatile Connectivity

These hoses are offered in standard lengths up to 100 meters, with the possibility for custom cuts to fit any installation. They support a range of connection types, such as crimped male/female ends or rapid quick connects, with fittings in stainless steel or brass adaptable for M16x2, G1/4, and similar sizes. Their minimal bending radius ensures easy routing in confined spaces.

FAQs of Dn2 Microbore Hoses:

Q: How can I determine the suitable length of Dn2 Microbore Hose for my setup?

A: You may specify any length up to 100 meters for your Dn2 Microbore Hose. Custom lengths are available to match the precise needs of your application, ensuring efficient installation without excess slack or stress on the hose.Q: What materials are used in the construction of Dn2 Microbore Hoses?

A: Dn2 Microbore Hoses are constructed using thermoplastic material reinforced with synthetic fibers and a steel wire braid. The outer cover is made from polyamide (PA) or polyurethane (PU), making them highly resistant to abrasion and harsh conditions.Q: Where can Dn2 Microbore Hoses be effectively utilized?

A: These hoses are ideal for use in high-pressure hydraulic systems, pressure testing, gauge lines, and monitoring fluids. Their reliability and robust construction make them suitable across industrial, testing, and fluid transfer environments.Q: What connection options are provided with Dn2 Microbore Hoses?

A: A variety of connection options are available, including crimped male or female fittings, as well as quick-connect designs. The fittings are made of stainless steel or brass and support multiple thread types like M16x2 or G1/4, allowing compatibility with diverse equipment.Q: How do Dn2 Microbore Hoses benefit high-pressure testing and monitoring applications?

A: Their high burst pressure ratingup to 2500 barand narrow inside diameter of 2 mm make them ideal for precise, safe transfer of hydraulic oil, air, or water in delicate monitoring and high-pressure test scenarios.Q: What is the typical process for installing Dn2 Microbore Hoses?

A: Installation is straightforward due to their flexible design and ultra-small bending radius (15 mm). Simply select the required fittings, cut to the appropriate length if needed, and connect either via crimped ends or quick-connects, depending on your systems requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refrigeration Hose Fittings Category

Microbore Hose Fittings

Price 1000 - 4000 INR / Number

Minimum Order Quantity : 50

Pressure : Up to 630 bar

Shape : Straight, Elbow, Tee

Medium : Other, Hydraulic Oil, Air, Water

Material : Other, Carbon Steel, Stainless Steel

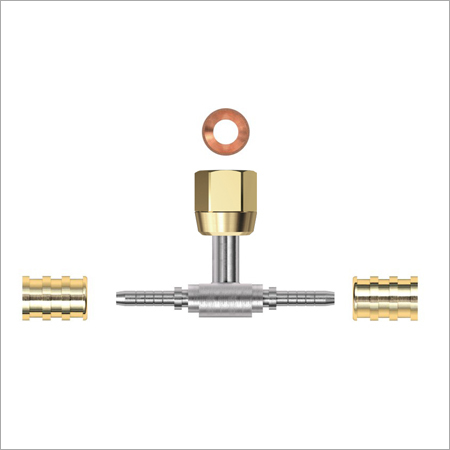

T Fitting With Female

Price 1000 - 4000 INR / Number

Minimum Order Quantity : 50

Pressure : Up to 10 bar

Shape : Tee

Medium : Other, Water, Gas, Oil

Material : Other, Brass

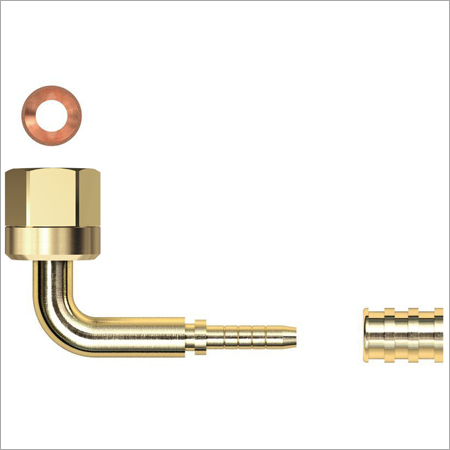

90 Degree Elbow Female Fitting

Price 1000.0 INR / Number

Minimum Order Quantity : 25

Pressure : Up to 400 Bar Bar

Shape : 90 Degree Elbow

Medium : Other, Gas, Oil, Water, Air

Material : Other

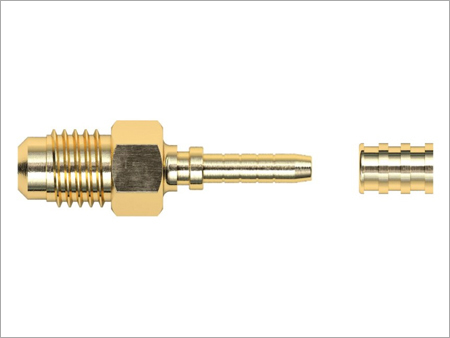

Straight Male Fitting

Price 1000 - 4000 INR / Number

Minimum Order Quantity : 25

Pressure : 016 Bar

Shape : Straight

Medium : Other, Air, Water, Inert Gas

Material : Other, Brass

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese